Ask for a reprint

email :

* Give your email

2017

ACL

|

N.Kang, P.Coddet, M.R.Ammar, H.Liao, C.Coddet, 'Characterization of the microstructure of a selective laser melting processed Al-50Si alloy: Effect of heat treatments', Mater. Charact. 130 243–249 (2017) doi:10.1016/j.matchar.2017.06.026

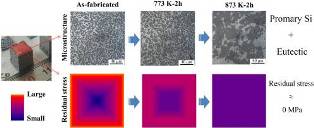

Due to the high heating/cooling rates involved in selective laser melting, the samples fabricated by this process, typically present high tensile residual stresses. The goal of this work was thus to investigate the effects of heat treatments on the microstructure and residual stress of selective laser melting processed Al-50Si alloy. Heat treatments were performed under temperatures ranged from 300 to 600 °C for 2 h with subsequent water quenching. The microstructure and the distribution of the residual stress state of the samples were determined respectively by metallographic techniques and by Raman spectroscopy before and after heat treatments. In the as-fabricated condition, the crystal sizes and the residual stress present an inhomogeneous distribution. Heat treatment at 300 °C allows a homogenization of the stress level without changing significantly the microstructure. While at higher temperatures, the average values of the residual stress decrease corresponding to an increase in the grain size.

|

|