Ask for a reprint

email :

* Give your email

2011

ACL

|

A.Azéma, B.Mille, P.Echegut, D.De Sousa Meneses, 'An experimental study of the welding techniques used on large Greek and Roman bronze statues', Historical Metallurgy 45 71-80 (2011)

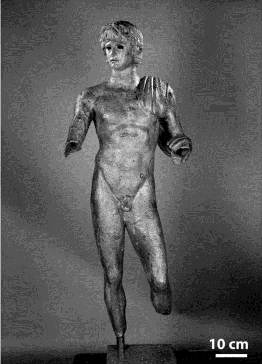

There are two key techniques in the manufacture of large Greek and Roman bronze statues. First, the statue is cast in several pieces by the indirect lost-wax process, and then the pieces are joined by a flow fusion welding process. The principle of ancient flow fusion welding consists of pouring molten bronze between the bronze pieces to be joined. Our laboratory experiments ontribute to the understanding of this joining process by studying the thermal and physico-chemical parameters that control the fusion welding of binary copper-tin alloys (bronzes). The results obtained were compared with observations of ancient joins on large bronze statues, but some questions remain unanswered. In particular, whatever experimental conditions were used, we were unable to produce a weld longer than a few centimetres, whereas some ancient welds can be up to a metre long. The use of a ‘magic’ additive, which could act as a welding flux is thus suspected.

|

|