Ask for a reprint

email :

* Give your email

2021

ACL

|

Maxime Puyo, Konstantina Christina Topka, Babacar Diallo, Raphaël Laloo, Cécile Genevois, Pierre Florian, Thierry Sauvage, Diane Samelor, François Senocq, Hugues Vergnes, Brigitte Caussat, Marie-Joëlle Menu, Nadia Pellerin, Constantin Vahlas, Viviane Turq, 'Beyond surface nanoindentation: Combining static and dynamic nanoindentation to assess intrinsic mechanical properties of chemical vapor deposition amorphous silicon oxide (SiOx) and silicon oxycarbide (SiOxCy) thin films', Thin Solid Films 735 138844 (2021) doi:10.1016/j.tsf.2021.138844

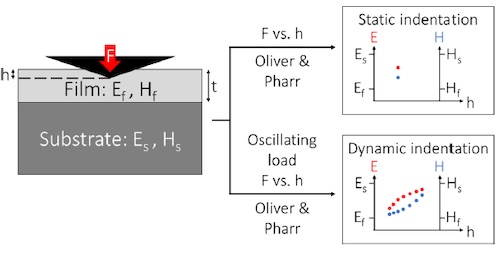

Nanoindentation is a common technique to assess the mechanical properties of bulk materials and films. Despite that, nanoindentation of thin films is not straightforward, given that the measured properties are composite information from a film/substrate system and depend on the penetration depth. By using dynamic indentation experiments and mathematical models, it has been possible to assess the intrinsic film properties of chemical vapor deposited silicon oxide (SiOx) and silicon oxycarbide (SiOxCy) thin films with thicknesses ranging from 60 to 700 nm. Bec rheological model and several mixing laws were reviewed. Using intrinsic film modulus and hardness, it was possible to establish correlations between these properties and the chemical composition and structural organization of the films.Nanoindentation is a well-known technique to assess the mechanical properties of bulk materials and films. Despite that, nanoindentation of thin films is not straightforward, given that the measured properties are composite information from a film/substrate system and depend on the indentation depth. By using dynamic indentation experiments and analytical or empirical models, we assessed the intrinsic film properties of chemical vapor deposited silicon oxide (SiOx) and silicon oxycarbide (SiOxCy) thin films with thicknesses ranging from 60 to 700 nm. In this work, the Bec rheological model and several mixing laws were reviewed. Measured Young modulus appeared to be affected by the substrate properties more than hardness: for the thinnest films, moduli were measured at ca. 90 GPa whereas intrinsic moduli were calculated at ca. 50 GPa. Using calculated intrinsic film modulus and hardness, it was possible to establish correlations between these properties, the chemical composition and the structural organization of the films.

|

|